Restoration and upgrades

The intention is to use this UC on trips because the Wab does not have a lot of water storage in its side tanks. This will allow us to run for a longer time without the need to stop for water. The committee looked at many UC tank wagons that were for sale before purchasing this one. The reason the committee chose this UC was because of its riveted construction. The rivets make the tank more in keeping with the historic nature of the society.

For more information about UC191.

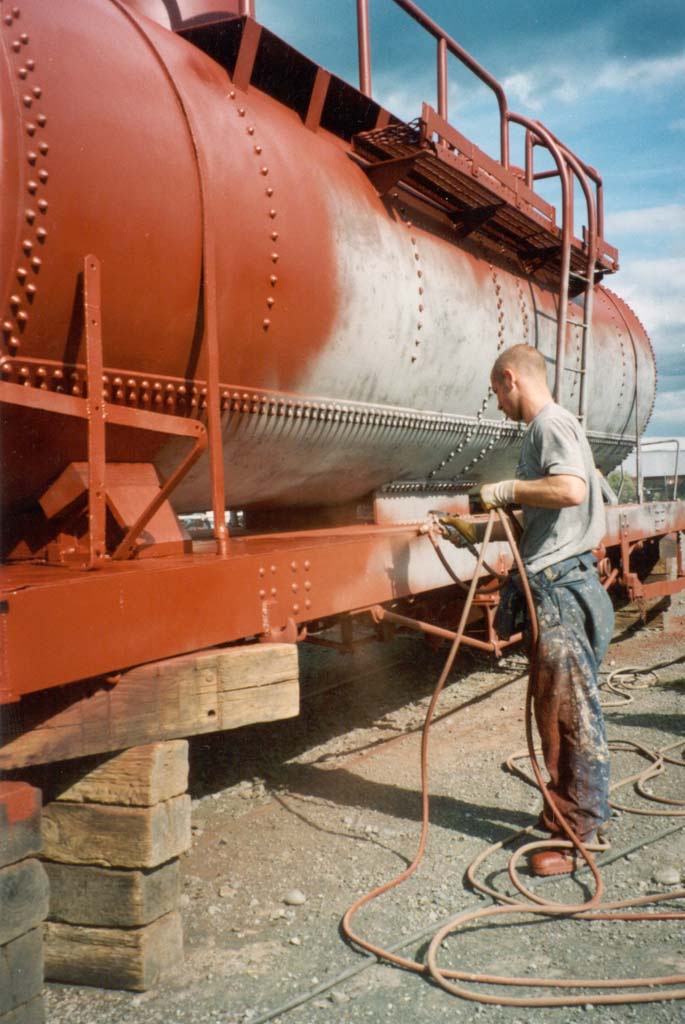

Sand Blasting the UC

Painting the UC

The UC is currently only primed with red paint.

The primed UC being pushed back into the depot by the F163.

The UC after its first coat of black paint. It look nearly a whole day to paint.

This UC is the biggest tank of Woodstock Bourbon in the country.

The two John’s fitting the plumbing to connect to the Wab and the F.

Replacing the pivot cone bolts. We inspected the bolts that hold the pivot cone under the UC wagon and found they needed replacement. We used our gantry crane yet again to lift the wagon and remove the bogie. Mike and Stuart then replaced the bolts.

We have fitted a 5KVA Petrol Generator to the UC. We use it to run the 1HP water pump and two large sets of lighting. The pump is used to keep the water in the Wab at the preferred level. The lights are used at night to service the Wab. The generator needed to be rebuilt into a new chassis as the original one was too large.

The control unit controls on the Wab always had a water level indictor, but one was never fitted to the UC as it had a sight glass. Over the years the sight glass has clouded up and become a problem to maintain, so fitting an electronic water indicator seemed to be a good idea. A new indicator using a seven segment display was created by Dr Nick Body.

The level indicator goes from 1 to 9 and then F for Full.

Mike showing Keith Jacob the recently fitted water level indicator.

The level indicator goes from 1 to 9 and then F for Full.

Lights donated and appreciated.

Uc 191 now has a new feature to help watering as these lights flash when almost full so the person on the hydrant can turn it off, without wasting water.